|

|

|

Category: » Swords » Japanese - Hanwei(Paul Chen) |

|

|

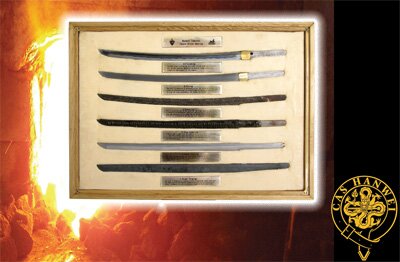

Hanwei Samurai Blade Display |

|

|

|

|

This is an elegant display articulating the highly skilled process of forging and polishing a high carbon steel Katana blade. Each step in the process is clearly displayed and explained, using smaller (18") versions of Katana blades that have undergone exactly the same processes as full-sized blades. This display is both aesthetically pleasing and highly educational.

1. Rough Forging: The blade is formed by hot forging a billet of high-carbon steel. The repeated hammering provides an even dispersion of carbon throughout the steel for uniform strength of the finished blade.

2. Rough Shaping: The scale is removed and the blade is shaped roughly to the required dimensions. At this stage, the steel is still in the annealed (soft) state and the blade is straight.

3. Clay Covering: A special clay is applied to the blade by hand, using a thin covering near the edge and a thicker layer over the rest of the blade. This results in a relatively quicker cooling of the edge during quenching, producing a hard edge and softer back.

4. Quenching: This is a critical part of the operation. The blade, with its clay covering, is heated to a predetermined temperature and quenched in a water bath. The shape and continuity of the hamon, the sori (blade curvature), and blade straightness are all determined by the care and skill exercised in quenching.

5. Sizing: The sori is adjusted if necessary, to set the point of balance and point of percussion, and de-scaled. Rough polishing is carried out to size the blade accurately. The habaki (blade collar) is fitted.

6. Finishing: Careful final polishing and fine finish work are carried out on the various surfaces to define ridgelines and bring out the beauty of the hamon.

|

|

Sold Out

|

|

|

|

|

|

|

|

|

|

|

Tags:

OH2154, Samurai Blade Display, sword, katana, Hanwei, forging katana,

|